Sep. 11, 2023

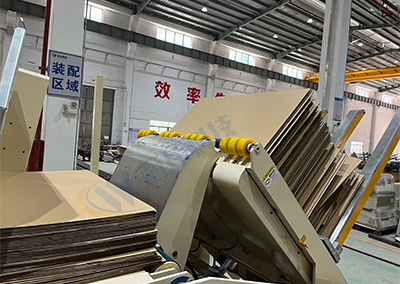

How prefeeder make the paper boards' flexo folding gluing printer run at highest speed?

A prefeeder plays a crucial role in enabling a flexo folding gluing printer to run at its highest speed. Here's how a prefeeder can contribute to maximizing the speed and efficiency of the printer:

Continuous feeding: A prefeeder ensures a continuous and uninterrupted supply of paper boards to the flexo folder gluer. By maintaining a steady flow of boards, it eliminates the need for the gluer to pause or slow down due to inconsistent or inadequate feeding. This constant supply allows the printer to operate at its highest speed without interruptions.

Precise board alignment: The prefeeder aligns and positions the paper boards accurately before they enter the flexo folder gluer. Proper alignment is critical to ensure that the boards are fed into the gluer in the correct position and orientation. By reducing misalignments and avoiding jams, the prefeeder enables the gluer to operate smoothly at higher speeds, minimizing downtime caused by manual adjustments or paper jams.

Proper board handling: A prefeeder is designed to handle a wide variety of paperboard sizes, weights, and qualities. It incorporates mechanisms such as suction cups, belts, or grippers to grip and handle the boards effectively. This ensures secure and reliable board feeding without slippage or damage, enabling higher speed operation of the printer while maintaining quality standards.

Integration with control systems: A prefeeder is typically integrated with the overall control system of the flexo folder gluer. This integration allows for seamless communication and synchronization between the prefeeder and the printer. The control system ensures that the prefeeder adjusts its speed and feeding rate to match the printer's requirements, facilitating smooth and efficient operation at the highest speed possible.

It is essential to choose a high-quality prefeeder that is specifically designed to meet the demands of your flexo folding gluing printer. Proper installation, regular maintenance, and operator training are also crucial factors to optimize the prefeeder's performance and ensure it contributes to running the printer at its highest speed, while maintaining quality and reliability.