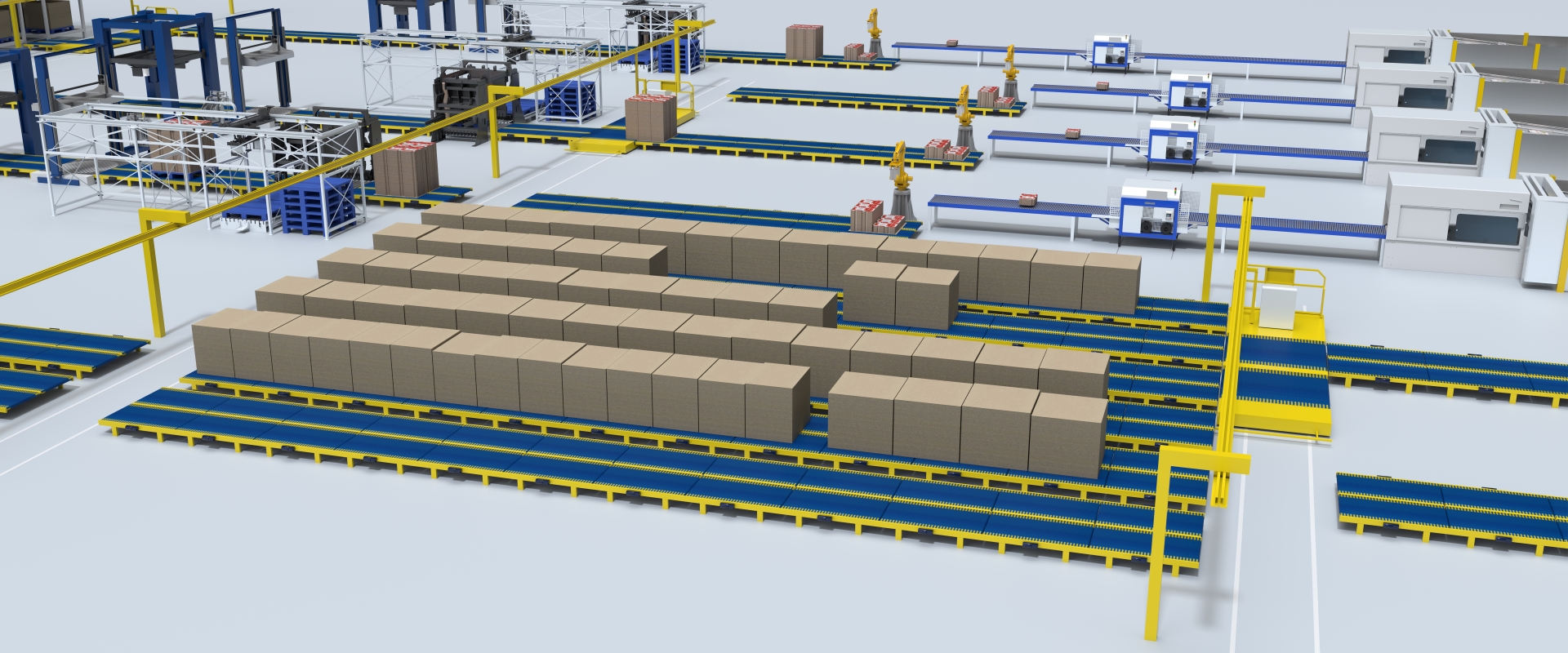

product details

Machines description

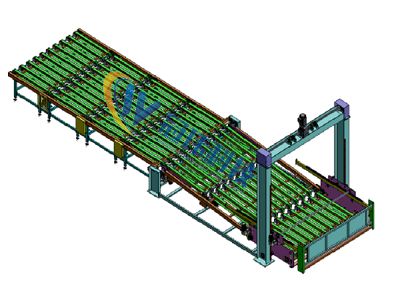

1) Equipment specifications: Overall dimension: L12500* W3450* H4000mm, working dimension: W2850* H300mm (maximum space);

2) Frame: The column adopts H-shaped steel HN400*200; the conveying frame adopts 120*80 square tube;

3) Conveying main body: seven independent conveying sections with frequency conversion control, two of which are controlled by servo system;

4) Conveying speed: power: 1.5KW, frequency conversion control Max 70m/min;

5) Elevating mechanism: 16A chain transmission, up and down movement mode;

6) Lifting speed: power: 3.0KW, frequency conversion control Max 35m/min;

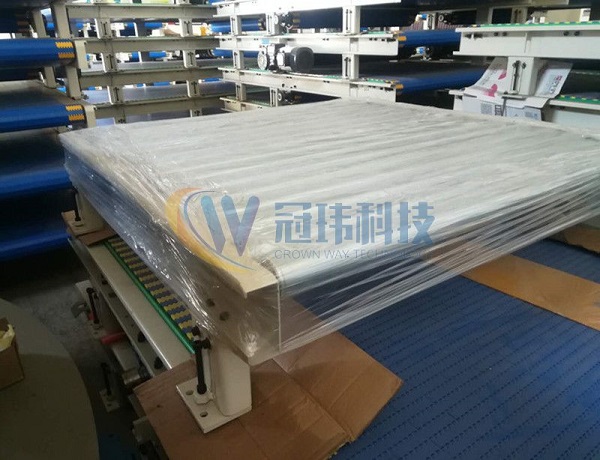

7) Conveyor belt: use 80mm wide pvc belt;

8) Belt support: 2mm stainless steel 201 plate is laser cut and bent;

9) Cardboard blocking mechanism: controlled by servo system, adjust the cardboard blocking space according to the order parameters;

10) Cardboard stop space: the maximum space between the back stop and the cardboard output edge: 1500mm;

11) Stack height: the effective height from the lower limit to the ground is 1950mm;

12) Paper splicing mechanism: Cylinder telescopic splicing/putting buffer cardboard, cylinder brand: CNSD Shangde Automation;

13) Motor brand: SUPROR/CPG Shengbang/INOVANCE Huichuan;

14) Detection components: each belt segment is conveyed independently, photoelectric detection, photoelectric brand: LEUZE;

15) Function: The belt section is independently conveyed and controlled by frequency conversion, and can quickly discharge cardboard at 0-70m/min, meeting the stacking of cardboard and reserved enough space for transportation/temporary storage

16) Elevating components: equipped with 2 sets of upper and lower switches, a total of 4 proximity switches, brand: SENVIEW Senjue

17) Detect and control the paper output area, prevent misoperation, and increase the mechanical limit at the same time;

18) Stack detection: 2 photoelectric devices are installed in the conveying section of the paper output belt in the rear section, brand: LEUZE,

19) The purpose is for detecting the height of each bundle of cardboard, control the lifting distance, and then stack the cardboard stably;

20) Electrical components: PLC: SIEMENS ;

21) Inverter: INOVANCE

22) Servo electrical: INOVANCE ;

23) Photoelectric switch: LEUZE ;

24) Proximity switch: SENVIEW ;

25) Cylinder: CNSD;

26) Bearing: transmission bearing: TR;

27) Deep groove ball bearing: China

28) Electric control: PLC program automatic control, manual operation;