product details

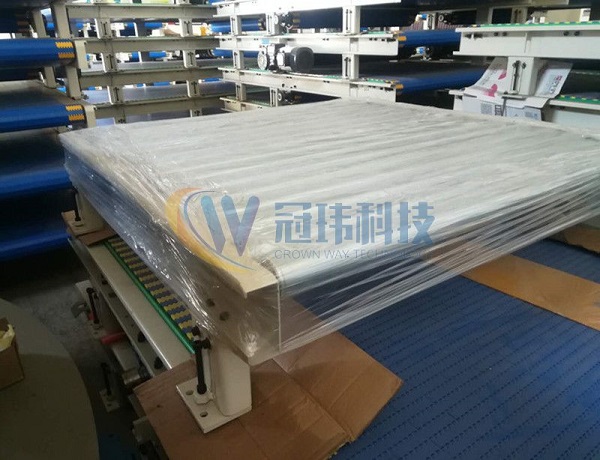

1. Purpose: In order to allow customers to improve production efficiency more effectively, design a heating system that is convenient to operate and effectively improve production efficiency according to customer needs, so as to improve the market competitiveness of customers.

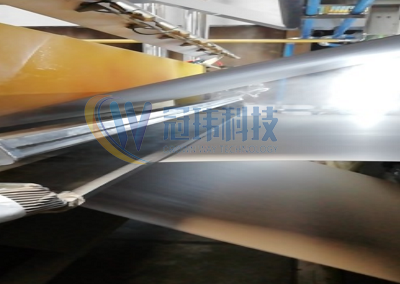

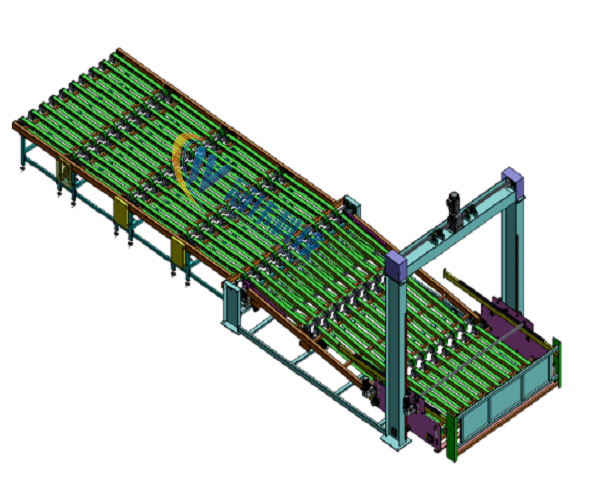

2. The heating system is composed of two parts: arc-shaped through-hole heating plate and split steam spraying structure; the heating plate is used to heat the middle layer paper, and the steam spraying structure is used to heat the upper corrugated edge, which can be heated in advance before entering the heating plate. After the five-layer paper is fed into the double-sided machine, it is combined with hot plate baking to make the paste paste quickly and gelatinize, so as to achieve the purpose of increasing the speed of the machine; no matter the material is high or low or the four-layer cardboard, the production speed can be effectively increased on the original basis.

3. Applicable models: All corrugated equipment on the market are applicable, machines’ width1.6~2.8m is suitable.

4. Main functions:

1) Press the button to control the heating on and off;

2) Manually adjust the steam quantitative;

3) Manually adjust the steam injection angle;

4) Adjust the height and angle of the heater according to different models;

5) When wearing 3 layers of paper, the heater can be raised manually to avoid burns;

6) Steam injection is heated in two sections, wide and narrow;